Asbestos Safety Guidelines

Asbestos is a silicate material widely used in different industries such as manufacturing, construction etc. due to its inherent physical properties. Despite, its wide application, it has a certain degree of health- related issues when exposed. Asbestos safe handling & exposure risk guidelines are imperative and need to be clearly documented for all the applications. Some of the key aspects are covered here such as: risk factors, The Control of Asbestos Regulations 2012 and general safety rules.

Appoint fully qualified, accredited & insured consultants”

Risk factors

Asbestos fibres are very small, lightweight and invisible to naked eye. Asbestos poses risk when the fibres are disturbed or damaged and get blended in the air, when inhaled the fibres get trapped in lungs or accumulates in the digestive system, if swallowed.

Some of the situations that can cause asbestos to be airborne are:

- Manufacturing of asbestos containing products

- Demolition of older buildings

- Remodelling, repairing or upgrading buildings

- Deterioration of older building and materials

- Clean up after natural disasters

Effective controls such as PPE kits, masks, gloves and effective asbestos handling guidelines can limit the major health risk for the people getting exposed to asbestos.

The Control of Asbestos Regulations 2012

These regulations are made to protect employees from asbestos exposure, it captures the following:

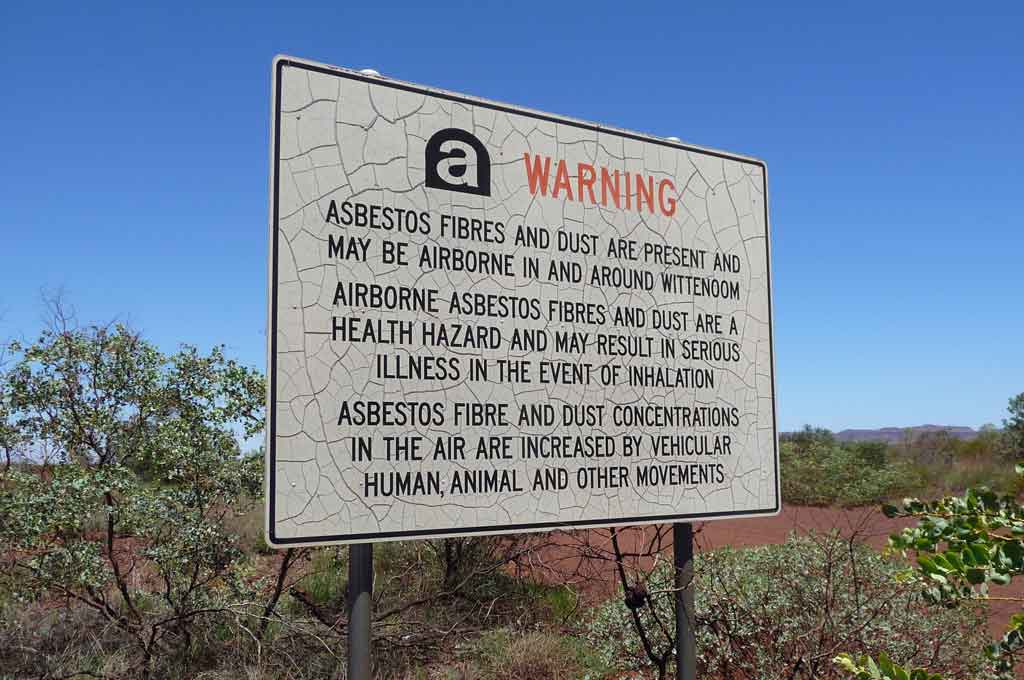

- Monitoring of asbestos fibres if it’s airborne, and if detected necessary precaution should be taken. If the site is construction, then regular monitoring and assessment should be done by a competent person or an asbestos specialist

- The Site must be separated with barricade tape (caution tape), and warning signs should be provided around the affected area

- Prohibiting smoking, eating or drinking in the affected area

- Proper PPE kit must be provided and used to prevent exposure

- Separate decontamination areas must be provided

- Proper hygiene practices should be followed in the premises including a designated place for meal.

- Periodic training requirement depending upon the workplace exposure and classification

- Mandatory training for all the workers dealing in asbestos related work including the housekeeping

- A continuous asbestos air monitoring system should be in place to provide regular asbestos level within the air

- Periodic medical examination for the workers working in affected area

General safety rules for asbestos

- Avoid activities such as sanding, drilling, cutting or grinding for the materials that may contain asbestos

- Stay out of attics and crawlspaces that may have the potential for asbestos dust

- Do not dust sweep or vacuum debris that may contain asbestos

- Do not put screws nails or other objects into asbestos ceiling or wall plasters

- Never use a power stripper on flooring that may contain asbestos

- Never sand or try to level asbestos flooring

- Report any damaged areas of building or any damaged building to the supervisor.

Wrapping Up

Safe handling of asbestos requires a proactive preventive approach to limit its impact, hence the asbestos consultants have opinioned comprehensive safety guidelines for performing the day to day activities, and effective governance for controlling the health related risk hazard due to asbestos.

Our experienced consultants can provide Asbestos inspection (Surveys) and UKAS accredited testing (Lab testing, air testing & 4-stage clearance procedures) services throughout UK and Ireland.

Here at Scopus, we treat all the clients with the highest integrity and aim to deliver the highest compliance standards.

Ready to take the next step? Send us a quote request or contact us here.